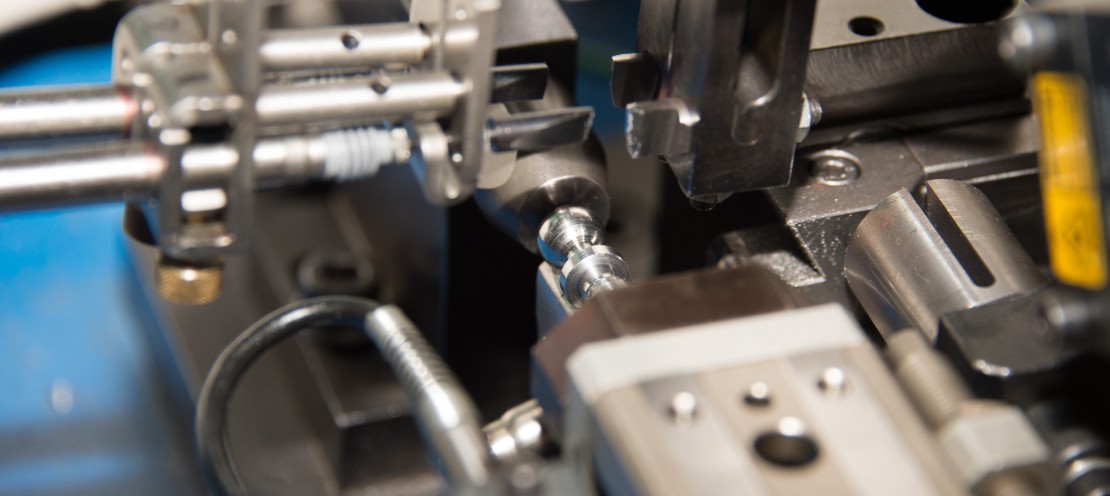

We are specialized in bar turning from Ø 1 to 25 mm in middle sized and large batches, including 100% automatic sorting of parts in order to guarantee zero defects.

| Company Name: | Raymond Dubosson SAS | ||

| Founded in: | 1963 | ||

| General Manager: | Sophie Revillod | ||

| Activities: | Bar machining Ø 1mm to Ø 25 mm | ||

| Quantities: | Middle and large sized batches, Finished part manufacturing on lathes | ||

| Machined materials: | All materials (specially Brass, Stainless steels, Steels, Copper alloys, ...) | ||

| Turnover: | 5 200 000 € | ||

| Employees: | 20 | ||

| Export part: | 80% (Europe, South America, North America, Turkey, China) | ||

| Quality insurance: | IATF 16949 and Iso 14001 (certified by the TÜV Rheinland) | ||

| Segments served: | 80% Automotive - 10% Connectors - 5% Leisure - 5% Other | ||

| Machine park: | Mini Ø - Maxi Ø | Lathes | Series |

| 1 - 25 | CNC (EVO DECO / Swiss DT 13 / Swiss GT 26 / New Mach) | Middle and Large | |

| 3 - 16 | MULTISPINLES (SAS16-6) | Large sized bathes | |

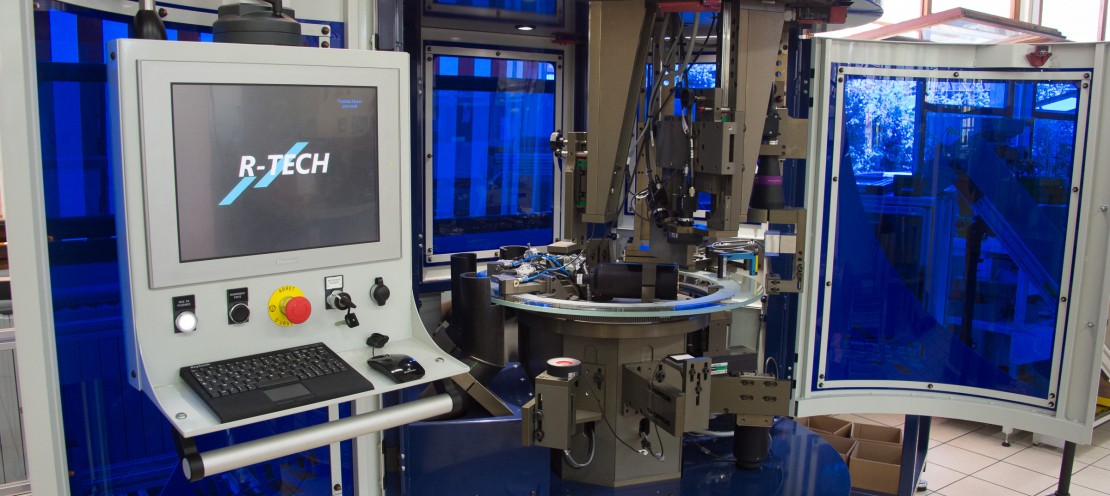

| Automatic sorting machine: | Middle sized and large series (100% control) | ||

| Finishing operations: | Sandblasting, Polishing, Washing, Degreasing, Technical cleanliness | ||

| External services: | Heat treatment, Surface treatment | ||

DECO 2000 and EvoDECO 10-16 latest generation are known to be the most precise and most productive machines of all. They manufacture complex parts and can thus meet all our customers' requirements.

Tornos SAS 16.6 lathes are well known for their reliability, durability, precision and an incredible productivity.

Company RAYMOND DUBOSSON's modern production means and skills as well as our team's thoroughness allow us to manufacture zero defect parts in large series.

Successful implementation of a machine park with tailor made sorting robots that meet all our cusotmers' requirements and guarantee zero defects for middle and large series.

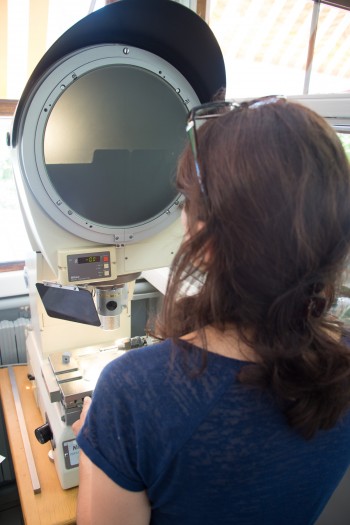

Our modern Measurement devices (Keyence, Mitutoyo 3D Machine) allow our team to carry out multiple inspections throughout the manufacturing process.

We are able to provide various internal finishing operations such as trowalizing, sand blasting, washing, greasing, special packing,...

Further operations such as heat treatments and surface treatments are provided by our external service partners.